astebo for energy efficiency

Professional engineering for efficiency and performance

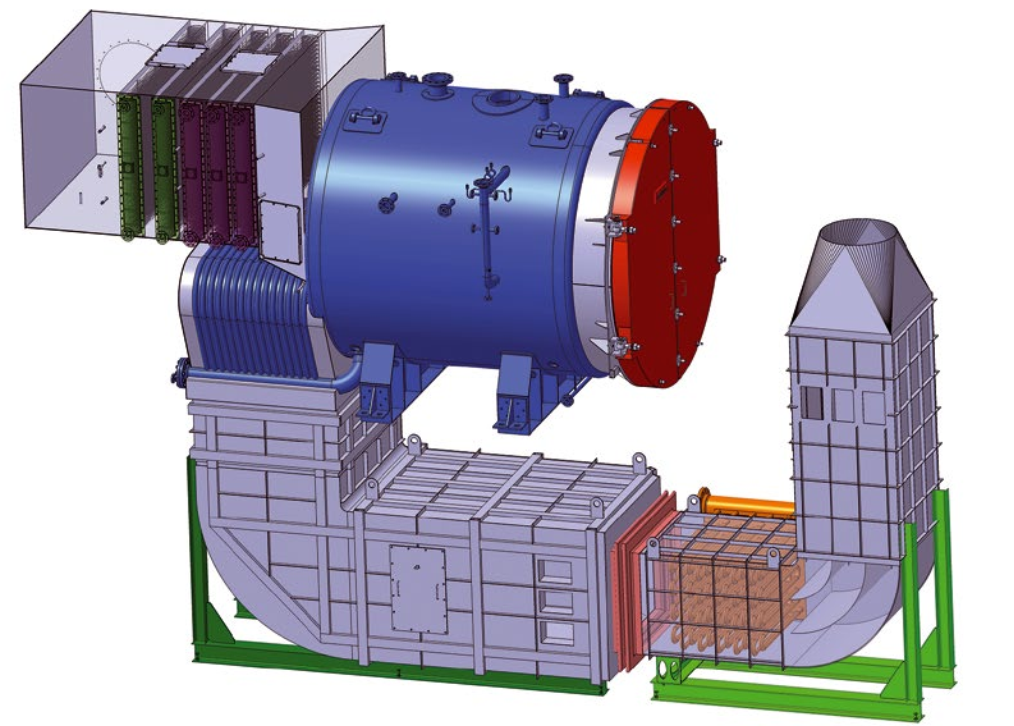

Waste heat boilers are sophisticated special constructions and serve to increase the energy efficiency of thermal plants – e.g. behind gas turbines or gas engines. The waste heat of industrial processes is made usable by waste heat boilers and utilised e.g. as process steam, for power generation, or as hot water.

This form of waste heat utilisation significantly increases the efficiency of the entire plant.