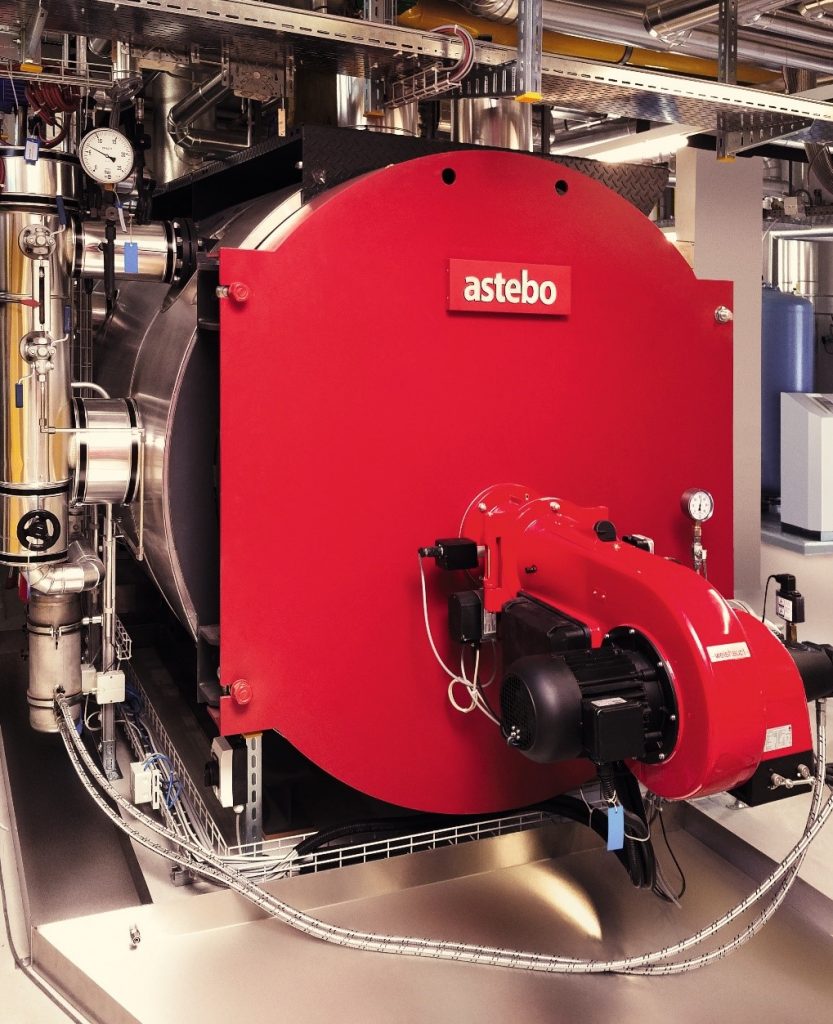

astebo for industry and trade

We make steam - for more than 40 years.

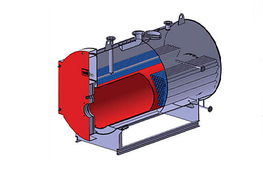

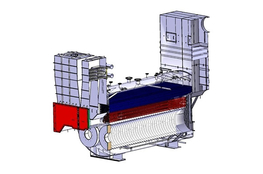

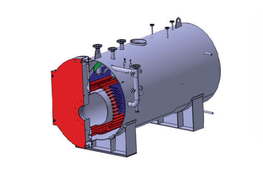

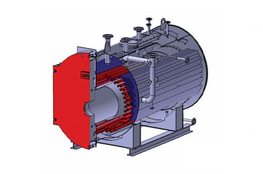

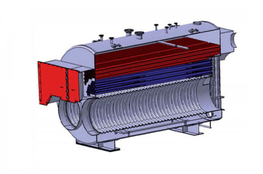

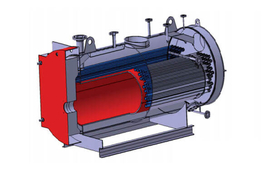

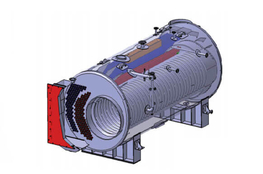

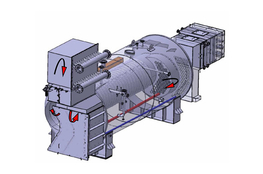

All astebo steam boilers are manufactured at the company’s headquarters in Marchtrenk (Upper Austria) in accordance with European standards for steam boilers and pressure equipment. All common welding methods such as MAG, MIG, TIG, and UP are used by our certified and experienced welders. Production meets all welding quality requirements in accordance with the relevant standards. Based on our expertise, we also carry out repair and maintenance work on existing boiler systems.

astebo gmbh designs customised, customer-specific systems together with the customer, starting with the system planning. Process engineering analyses and extensive industry experience are combined for plant dimensioning and selection of the optimum plant components. Professional basic engineering supports the future operator with the submission and any necessary construction measures. Quality-controlled order processing with corresponding detail engineering, 3D production drawings from the in-house design department and a commercially/technically experienced project management team guarantee on-time order processing and commissioning of the boiler plant.