astebo for complete solutions

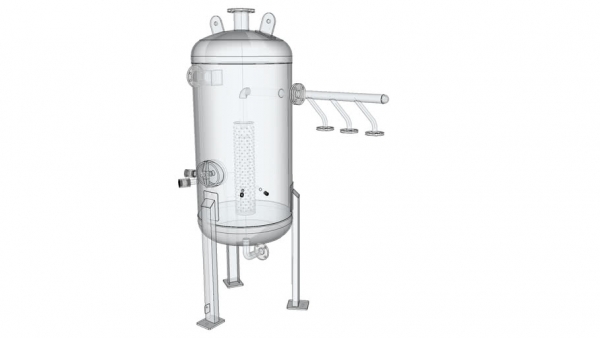

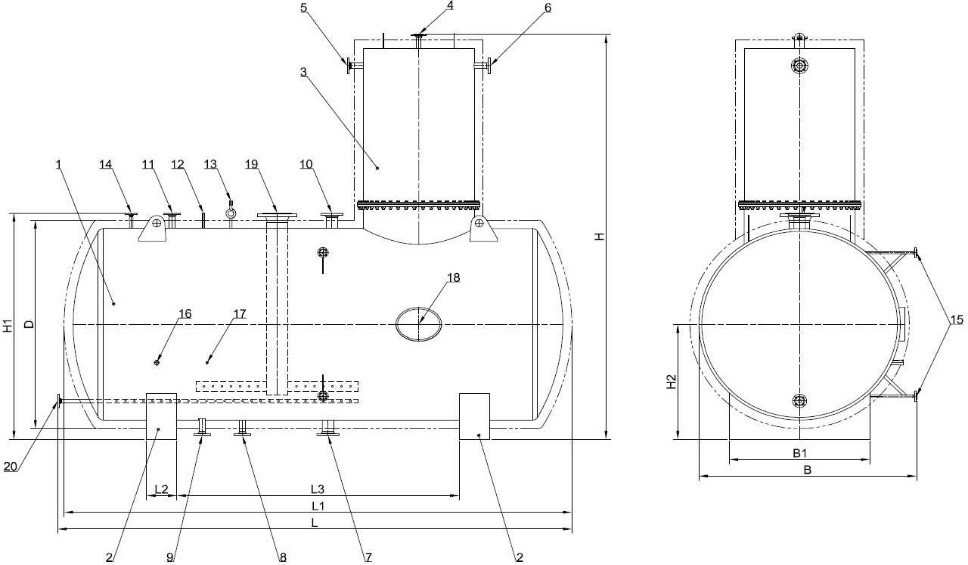

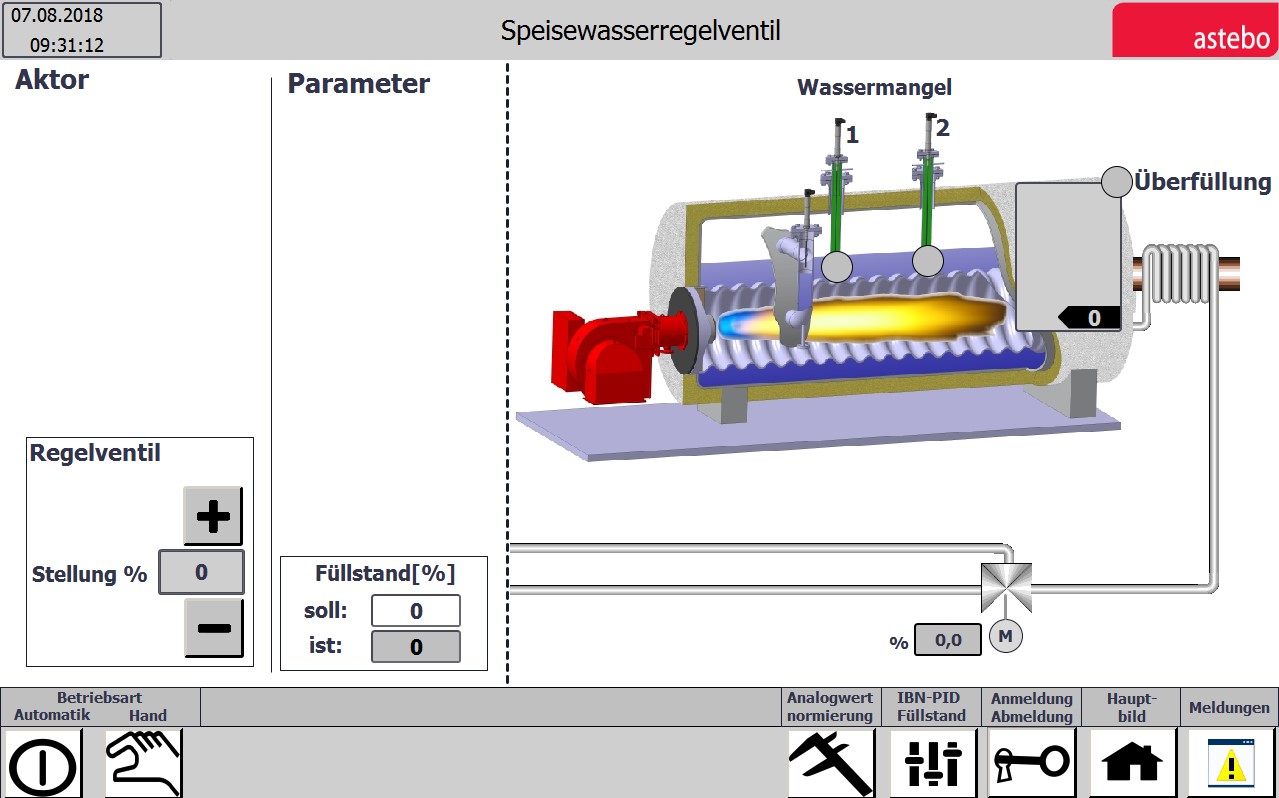

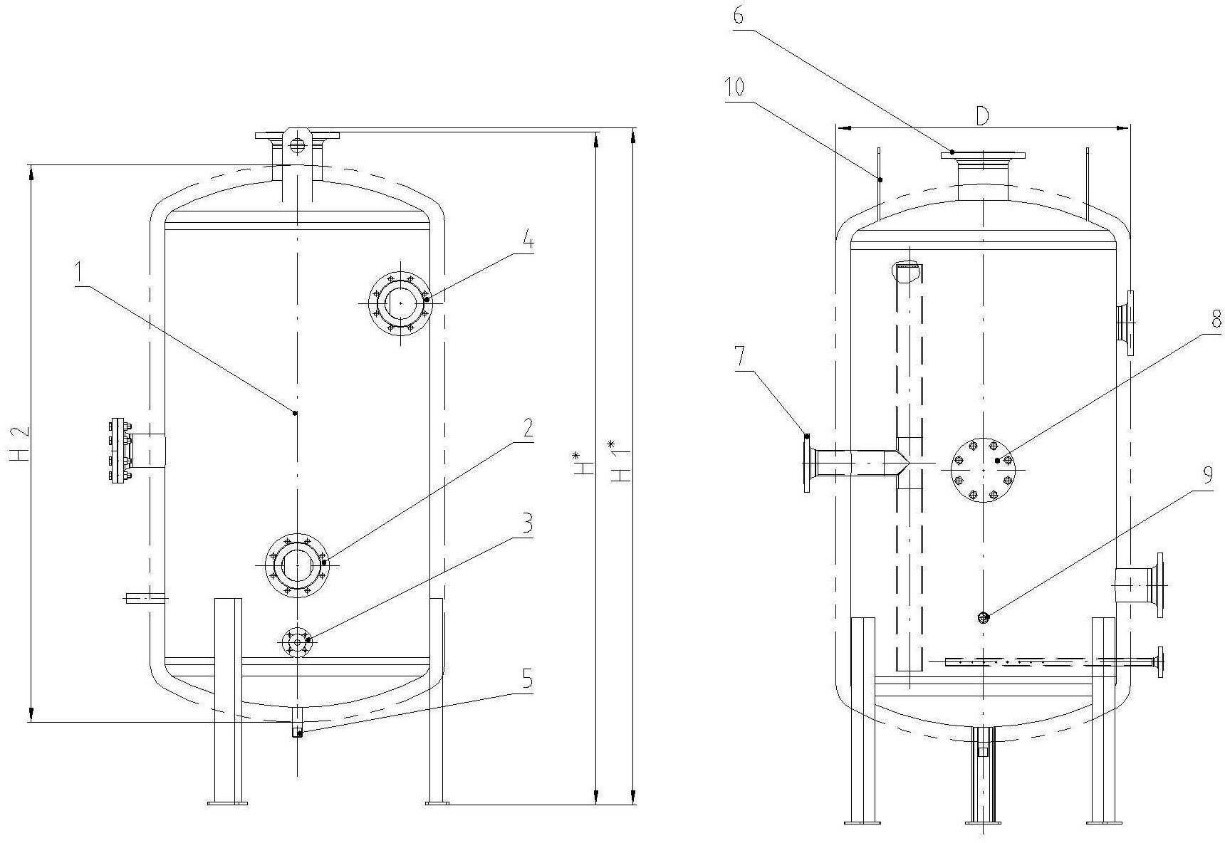

Feedwater tanks

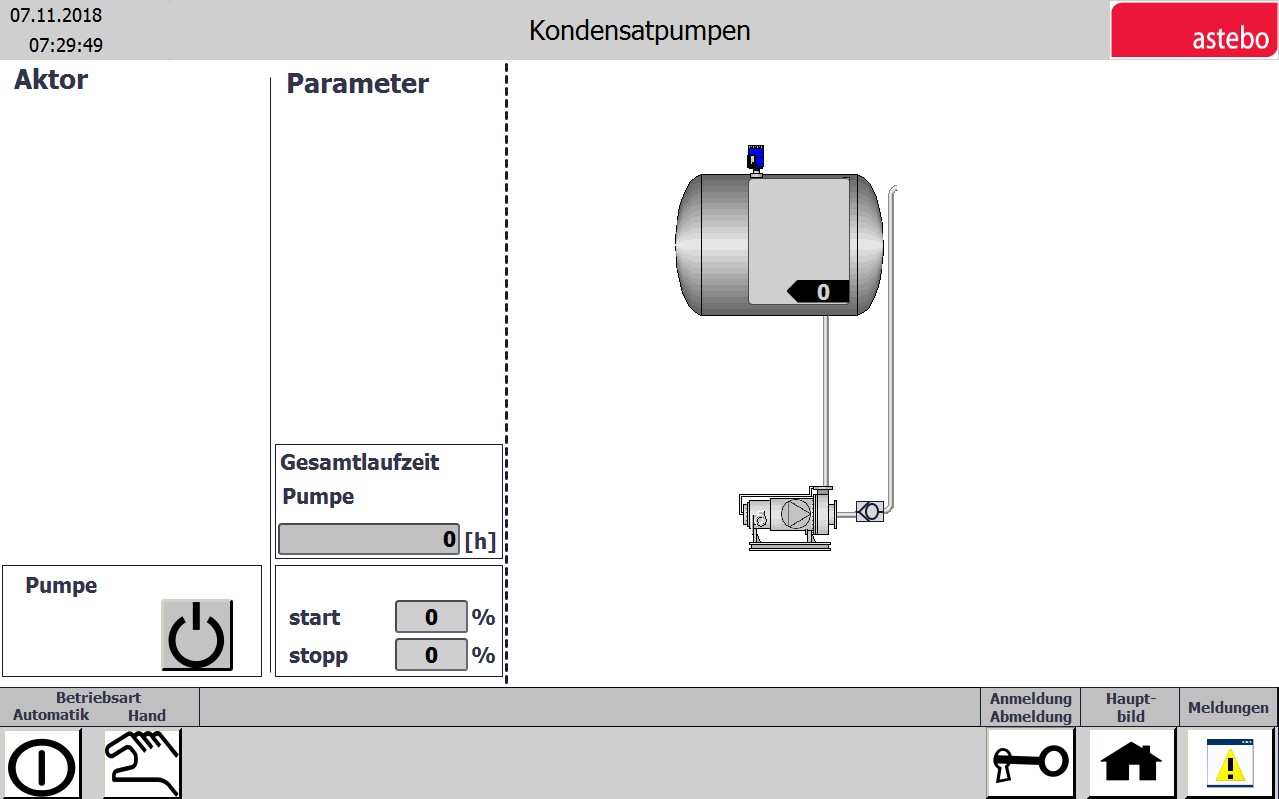

Condensate tanks

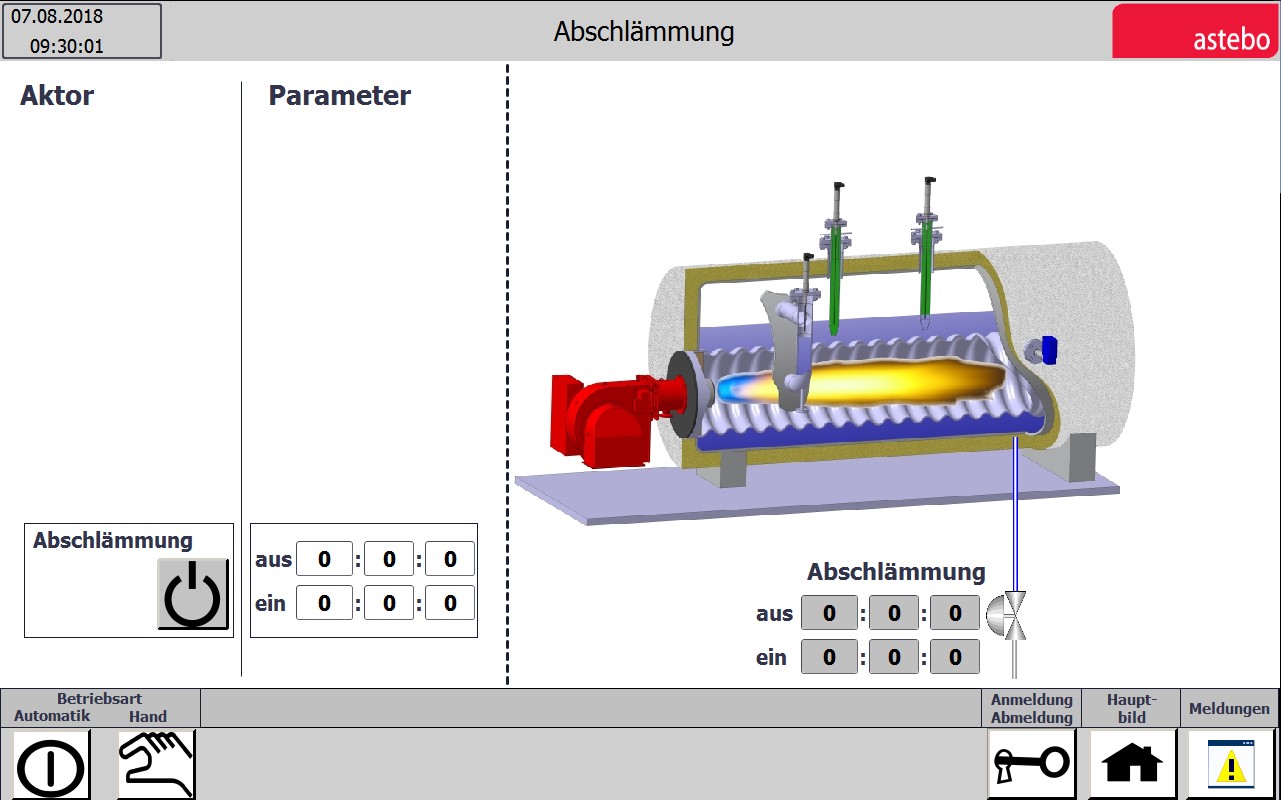

Blowdown tanks

individual - ideally matched - perfectly integrated

astebo develops and produces all the tanks required for the respective boiler system. These are usually feedwater, blowdown and condensate tanks. The design of all tanks used in boiler plants is precisely matched to the plant characteristics by our engineers.